PUR is moisture curing reactive polyurethane hot melt adhesive. The main component is isocyanate – terminated polyurethane prepolymer. In the state of high temperature after heating, PUR adhesive molecules react with water or active hydrogen substances in the air or on the adhesive to form part of the cross-networking structure, so that the bonding strength, chemical resistance, heat resistance, hydrolysis resistance and other properties are better than the general hot melt adhesive. The adhesive property and toughness (elasticity) of PUR can be adjusted, and it has the thermoplastic and cold setting property of common hot melt adhesive. The adhesive operation is simple, and the adhesive range is wide and the performance is adjustable.

PUR hot melt glue laminating machine, solvent-less, is the ideal green environmental protection glue, pollution-free production emission problem, save energy; hot melt does not contain water, no drying, fast compounding speed.

Composite process wet solid reaction, irreversible, strong adhesion washable; Melt glue system is independent, melt glue full speed is fast; dot mesh glue, the finished product permeability is good, strong three-dimensional sense.

Characteristics of PUR hot melt glue laminating machine:

1. The hot melt glue contains solvent-less, is the ideal green glue.

2. Hot melt adhesive bonding fastness is strong, a small amount of adhesive can achieve the strength of traditional adhesive.

3. Heat source is oil heat, heating speed is fast, heat is stable and uniform.

4. Glue melt system independent, glue melt full speed.

5.Dot mesh glue, the finished product breathable, strong three-dimensional sense.

6. No residual solvent products, pollution-free production emissions, energy saving, small footprint.

7. The composite process of wet solid reaction, irreversible, good adhesion fastness, washable.

8. Machine humanized design, PLC person-machine interface control, precise clearance adjustment, save operators.

9. The compound process is fully controlled by linkage, and the base material is light and soft with good hand feeling.

10. PUR hot melt glue laminating machine contains no water and solvent, no drying, fast composite speed.

11. Both a small amount of diversified production design, cost saving, digital control system, make better operation.

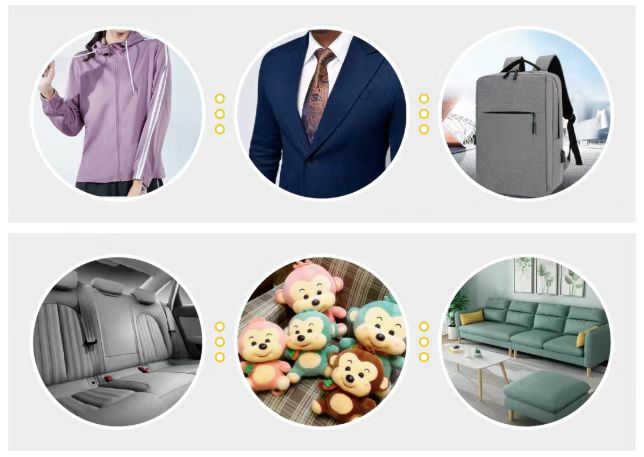

For apparel, composite processing combines fabric with fabric or fabric with film. First of all in wear-resistant and washable aspects is much better than a single fabric to do raw materials. For sports clothing, such as mountaineering clothing fabric need composite processing, because mountaineering clothing not only needs wear-resistant and washable, but also warm, breathable, moisture permeability, windproof and other functions. The material of car cushion also needs composite processing. Fabrics or leather as a surface cloth, and foam is soft, elastic and other characteristics. Also, because of the use of composite glue with fire prevention function, so there is a certain safety function to ensure that the car seat made of this than the general car seat market competitiveness.

Solvent and water dosage form is required when the adhesive curing oven (need) to the existing oven to overhaul or may be, and take up larger workshop space, increase the plant energy consumption at the same time, will produce more waste water and sludge, more strict production run, the disadvantage of solvent adhesive is obvious, is not very environmentally friendly solvent (most harmful). The environmental pollution of solvent-based adhesives is very serious. With the improvement of people’s environmental awareness and the establishment and improvement of relevant laws, the application of solvent-based adhesives is declining at a certain speed every year. Water glue has poor water resistance, poor electrical characteristics, long drying time, large energy consumption and other shortcomings, its application is also declining at a certain rate every year. PUR hot melt adhesive composite machine with the traditional solvent rubber (oil) and water soluble adhesive both, compared to PUR type hot melt with stable performance, high utilization rate of raw materials, production speed, high yield, and the advantages of small equipment cover an area of an area small and investment, and effectively solve the inherent defects in the traditional process, it is an ideal production tools to compound machine industry upgrading.

Post time: Jul-19-2022